Intro

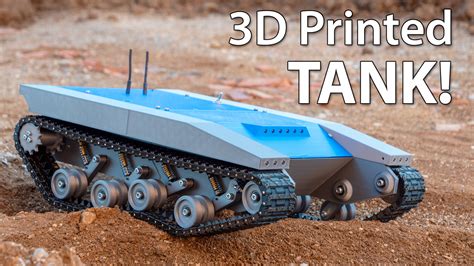

Discover the 3 key benefits of 3D printed tanks, revolutionizing water storage solutions with enhanced durability, cost-effectiveness, and sustainability. Learn how additive manufacturing is transforming tank design and construction, offering improved performance, reduced maintenance, and eco-friendly options for industrial, commercial, and residential applications.

The use of 3D printing technology has revolutionized various industries, including the manufacturing of tanks. 3D printed tanks offer several benefits over traditional manufacturing methods. In this article, we will explore three key benefits of 3D printed tanks.

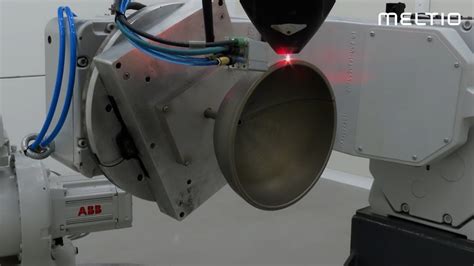

3D printing technology has advanced significantly in recent years, enabling the creation of complex structures and products with high precision and accuracy. The use of 3D printing in tank manufacturing has gained popularity due to its potential to reduce production time, increase efficiency, and improve product quality.

One of the primary benefits of 3D printed tanks is the significant reduction in production time. Traditional tank manufacturing methods involve multiple stages, including design, prototyping, tooling, and production, which can take several months or even years to complete. In contrast, 3D printing enables the rapid creation of tank prototypes and production-ready parts, reducing the overall production time to just a few weeks or days.

This reduction in production time is attributed to the additive nature of 3D printing, which allows for the creation of complex geometries and structures without the need for molds or tooling. Additionally, 3D printing enables the simultaneous production of multiple parts, further reducing production time.

Increased Efficiency

Another benefit of 3D printed tanks is increased efficiency. Traditional tank manufacturing methods often result in material waste and inefficiencies due to the use of subtractive manufacturing techniques. In contrast, 3D printing is an additive process that creates products by adding layers of material, reducing material waste and energy consumption.

Furthermore, 3D printing enables the creation of complex geometries and structures that cannot be produced using traditional manufacturing methods. This enables the design of more efficient tank systems, such as optimized fuel tanks and lighter-weight structures, which can improve overall system performance.

Design Flexibility

3D printing technology also offers significant design flexibility, enabling the creation of complex tank geometries and structures that cannot be produced using traditional manufacturing methods. This design flexibility allows engineers to optimize tank designs for specific applications, such as reducing weight or improving fuel efficiency.

Additionally, 3D printing enables the creation of customized tank designs for specific industries or applications, such as aerospace, automotive, or energy. This design flexibility is particularly beneficial in industries where tank designs must meet specific requirements or regulations.

Benefits of 3D Printed Tanks in Aerospace

The use of 3D printed tanks in the aerospace industry offers several benefits, including reduced weight, improved fuel efficiency, and increased design flexibility. 3D printed tanks can be designed to optimize fuel efficiency, reducing the overall weight of the tank and improving aircraft performance.

Additionally, 3D printing enables the creation of complex tank geometries and structures that cannot be produced using traditional manufacturing methods. This design flexibility allows engineers to optimize tank designs for specific aerospace applications, such as reducing weight or improving fuel efficiency.

Benefits of 3D Printed Tanks in Automotive

The use of 3D printed tanks in the automotive industry offers several benefits, including improved fuel efficiency, reduced weight, and increased design flexibility. 3D printed tanks can be designed to optimize fuel efficiency, reducing the overall weight of the tank and improving vehicle performance.

Additionally, 3D printing enables the creation of complex tank geometries and structures that cannot be produced using traditional manufacturing methods. This design flexibility allows engineers to optimize tank designs for specific automotive applications, such as reducing weight or improving fuel efficiency.

Benefits of 3D Printed Tanks in Energy

The use of 3D printed tanks in the energy industry offers several benefits, including improved efficiency, reduced weight, and increased design flexibility. 3D printed tanks can be designed to optimize energy storage and transfer, reducing the overall weight of the tank and improving system performance.

Additionally, 3D printing enables the creation of complex tank geometries and structures that cannot be produced using traditional manufacturing methods. This design flexibility allows engineers to optimize tank designs for specific energy applications, such as reducing weight or improving efficiency.

Future of 3D Printed Tanks

The use of 3D printed tanks is expected to continue to grow in the future, driven by advances in 3D printing technology and the increasing demand for efficient and lightweight tank systems. As 3D printing technology continues to evolve, we can expect to see even more complex and efficient tank designs, further improving system performance and reducing production time.

3D Printed Tanks Image Gallery

What are the benefits of 3D printed tanks?

+The benefits of 3D printed tanks include reduced production time, increased efficiency, and improved design flexibility.

What industries can benefit from 3D printed tanks?

+Industries such as aerospace, automotive, and energy can benefit from 3D printed tanks.

What is the future of 3D printed tanks?

+The use of 3D printed tanks is expected to continue to grow in the future, driven by advances in 3D printing technology and the increasing demand for efficient and lightweight tank systems.

We hope this article has provided valuable insights into the benefits of 3D printed tanks. If you have any questions or comments, please feel free to share them below.