Intro

Selecting the right fuel tank is crucial for safe and efficient storage. Discover 5 essential ways to choose a better built fuel tank, including considering materials, capacity, and safety features. Learn how to evaluate tank thickness, coatings, and UL certifications to ensure compliance and prevent leaks, corrosion, and accidents.

As the demand for fuel tanks continues to grow, it's essential to choose a reliable and durable option that meets your specific needs. With so many options available in the market, selecting the right fuel tank can be overwhelming. In this article, we'll explore five ways to choose a better-built fuel tank that ensures optimal performance, safety, and longevity.

1. Material Selection: The Foundation of a Durable Fuel Tank

When it comes to fuel tanks, the material used is crucial in determining its durability and performance. The most common materials used for fuel tanks are steel, aluminum, and polyethylene. Steel fuel tanks are known for their strength and durability, making them a popular choice for heavy-duty applications. Aluminum fuel tanks, on the other hand, are lightweight and corrosion-resistant, making them ideal for smaller applications. Polyethylene fuel tanks are made from a durable plastic material that is resistant to corrosion and cracking.

When choosing a fuel tank, consider the environment in which it will be used. For example, if the tank will be exposed to harsh weather conditions or corrosive substances, a steel or polyethylene tank may be a better option.

Benefits of Each Material:

- Steel: Strong, durable, and resistant to punctures

- Aluminum: Lightweight, corrosion-resistant, and easy to install

- Polyethylene: Resistant to corrosion, cracking, and UV damage

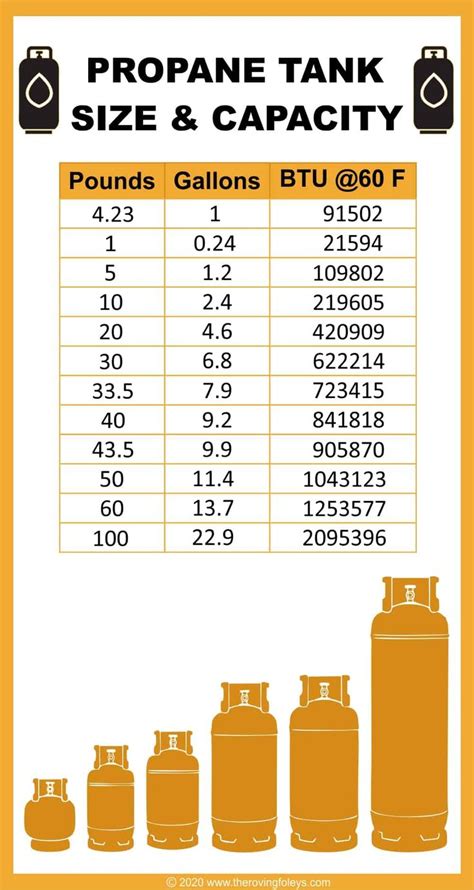

2. Size and Capacity: Choosing the Right Fit for Your Needs

The size and capacity of your fuel tank will depend on your specific needs and requirements. Consider the amount of fuel you need to store, the space available for installation, and the flow rate required. It's essential to choose a tank that is the right size for your application to avoid overfilling or underfilling.

Factors to Consider:

- Space constraints: Measure the available space for installation to ensure the tank fits comfortably.

- Fuel requirements: Calculate the amount of fuel needed to meet your demands.

- Flow rate: Determine the required flow rate to ensure the tank can supply fuel efficiently.

3. Safety Features: Prioritizing Protection and Prevention

Safety features are a critical aspect of fuel tank selection. Look for tanks with built-in safety features such as overfill protection, venting systems, and leakage detection. These features can help prevent accidents, reduce the risk of fires, and minimize environmental damage.

Safety Features to Look for:

- Overfill protection: Prevents the tank from overflowing and reduces the risk of spills.

- Venting systems: Allows air to enter the tank as fuel is dispensed, reducing the risk of vacuum collapse.

- Leakage detection: Alerts you to potential leaks or cracks in the tank.

4. Certifications and Compliance: Ensuring Regulatory Adherence

When choosing a fuel tank, it's essential to ensure that it meets regulatory requirements and industry standards. Look for tanks that are certified by reputable organizations such as the American Society of Mechanical Engineers (ASME) or the Underwriters Laboratories (UL). These certifications ensure that the tank meets strict safety and performance standards.

Certifications to Look for:

- ASME certification: Ensures the tank meets strict safety and performance standards.

- UL certification: Verifies that the tank meets safety standards for fire resistance and leakage.

- DOT certification: Ensures the tank meets regulatory requirements for transportation.

5. Maintenance and Support: Ensuring Long-Term Performance

Finally, consider the maintenance and support requirements of your fuel tank. Look for tanks with easy-to-access components, simple maintenance procedures, and reliable customer support. A well-maintained tank can ensure optimal performance, reduce downtime, and extend its lifespan.

Factors to Consider:

- Accessibility: Choose a tank with easy-to-access components for simple maintenance.

- Maintenance procedures: Opt for a tank with straightforward maintenance procedures.

- Customer support: Select a manufacturer with reliable customer support and technical assistance.

Fuel Tank Image Gallery

What is the importance of material selection in fuel tank construction?

+Material selection is crucial in determining the durability and performance of a fuel tank. Different materials offer unique benefits and drawbacks, and selecting the right material can ensure optimal performance and safety.

How do I determine the right size for my fuel tank?

+To determine the right size for your fuel tank, consider the amount of fuel you need to store, the space available for installation, and the flow rate required. It's essential to choose a tank that is the right size for your application to avoid overfilling or underfilling.

What safety features should I look for in a fuel tank?

+Look for fuel tanks with built-in safety features such as overfill protection, venting systems, and leakage detection. These features can help prevent accidents, reduce the risk of fires, and minimize environmental damage.

By considering these five factors, you can choose a better-built fuel tank that meets your specific needs and requirements. Remember to prioritize material selection, size and capacity, safety features, certifications and compliance, and maintenance and support. With the right fuel tank, you can ensure optimal performance, safety, and longevity.