Intro

Boost your warehouse efficiency with expert tips on optimizing conditionnement sur palette. Discover the top 5 ways to streamline your pallet packaging process, reduce costs, and increase productivity. Learn how to maximize pallet space, minimize material waste, and improve supply chain logistics for a more efficient and sustainable operation.

In today's fast-paced logistics and shipping industry, businesses are constantly seeking ways to optimize their operations and reduce costs. One crucial aspect of this is the conditionnement sur palette, or pallet packaging, process. In this article, we will explore five ways to optimize your conditionnement sur palette operations, making your business more efficient and competitive.

Understanding Conditionnement Sur Palette

Conditionnement sur palette refers to the process of preparing and packaging goods on pallets for shipping and storage. This process involves several stages, including product selection, palletization, and packaging. Optimizing this process can help businesses reduce costs, improve efficiency, and enhance customer satisfaction.

Benefits of Optimizing Conditionnement Sur Palette

Optimizing your conditionnement sur palette operations can bring numerous benefits to your business. Some of these benefits include:

- Reduced labor costs: By streamlining the palletization process, businesses can reduce the time and labor required to prepare goods for shipping.

- Improved efficiency: Optimizing conditionnement sur palette can help businesses improve their overall efficiency, enabling them to process more orders and meet customer demands more effectively.

- Enhanced customer satisfaction: By ensuring that goods are properly packaged and palletized, businesses can reduce the risk of damage during shipping, leading to increased customer satisfaction.

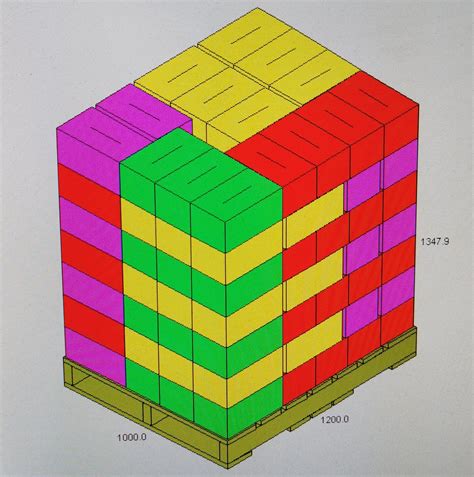

1. Implementing a Palletization Strategy

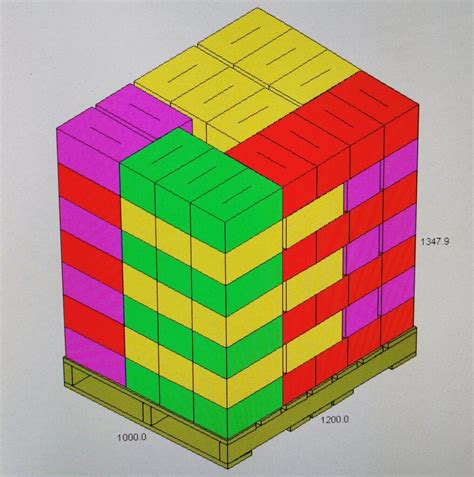

One of the most effective ways to optimize conditionnement sur palette is to implement a palletization strategy. This involves analyzing your business's specific needs and developing a plan to optimize the palletization process. Some key considerations when developing a palletization strategy include:

- Product dimensions and weight: Understanding the dimensions and weight of your products is crucial when developing a palletization strategy.

- Pallet size and type: Selecting the right pallet size and type can help optimize the palletization process and reduce waste.

- Packaging materials: Choosing the right packaging materials can help protect goods during shipping and reduce the risk of damage.

Best Practices for Palletization

When implementing a palletization strategy, there are several best practices to keep in mind. Some of these include:

- Using a consistent pallet size and type

- Optimizing product placement on the pallet

- Using the right packaging materials

- Ensuring proper pallet labeling and tracking

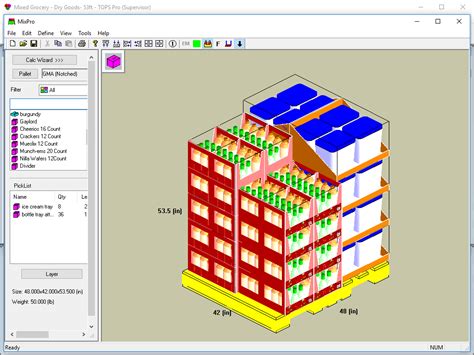

2. Investing in Automation Technology

Investing in automation technology can be an effective way to optimize conditionnement sur palette operations. Automation technology, such as palletizing robots and automated packaging systems, can help streamline the palletization process and reduce labor costs. Some benefits of automation technology include:

- Increased efficiency: Automation technology can help businesses process more orders and meet customer demands more effectively.

- Reduced labor costs: By automating the palletization process, businesses can reduce the time and labor required to prepare goods for shipping.

- Improved accuracy: Automation technology can help reduce errors and improve the accuracy of the palletization process.

Types of Automation Technology

There are several types of automation technology that can be used to optimize conditionnement sur palette operations. Some of these include:

- Palletizing robots: These robots can help automate the palletization process and improve efficiency.

- Automated packaging systems: These systems can help automate the packaging process and reduce waste.

- Conveyor systems: These systems can help automate the movement of goods and improve efficiency.

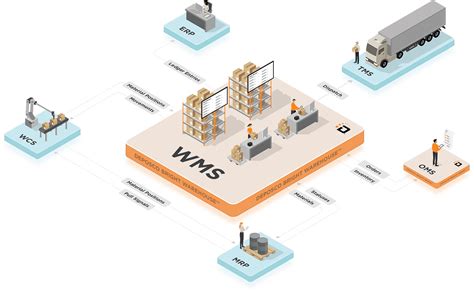

3. Implementing a Warehouse Management System

Implementing a warehouse management system (WMS) can be an effective way to optimize conditionnement sur palette operations. A WMS can help businesses track and manage inventory, optimize the palletization process, and improve efficiency. Some benefits of a WMS include:

- Improved inventory management: A WMS can help businesses track and manage inventory more effectively.

- Optimized palletization: A WMS can help businesses optimize the palletization process and reduce waste.

- Improved efficiency: A WMS can help businesses improve efficiency and reduce labor costs.

Key Features of a WMS

When selecting a WMS, there are several key features to consider. Some of these include:

- Inventory management: The ability to track and manage inventory is crucial when optimizing conditionnement sur palette operations.

- Palletization optimization: A WMS should be able to optimize the palletization process and reduce waste.

- Reporting and analytics: A WMS should provide reporting and analytics capabilities to help businesses make informed decisions.

4. Training and Development

Providing training and development opportunities for employees can be an effective way to optimize conditionnement sur palette operations. By investing in employee training and development, businesses can improve efficiency, reduce errors, and enhance customer satisfaction. Some benefits of training and development include:

- Improved efficiency: Trained employees can help improve efficiency and reduce labor costs.

- Reduced errors: Trained employees can help reduce errors and improve the accuracy of the palletization process.

- Enhanced customer satisfaction: Trained employees can help enhance customer satisfaction by providing better service and support.

Types of Training and Development

There are several types of training and development opportunities that can be provided to employees. Some of these include:

- On-the-job training: This type of training provides employees with hands-on experience and training.

- Classroom training: This type of training provides employees with instruction and training in a classroom setting.

- Online training: This type of training provides employees with instruction and training online.

5. Continuous Improvement

Continuous improvement is an essential aspect of optimizing conditionnement sur palette operations. By regularly evaluating and improving processes, businesses can stay competitive and adapt to changing market conditions. Some benefits of continuous improvement include:

- Improved efficiency: Continuous improvement can help businesses improve efficiency and reduce labor costs.

- Reduced waste: Continuous improvement can help businesses reduce waste and improve the accuracy of the palletization process.

- Enhanced customer satisfaction: Continuous improvement can help businesses enhance customer satisfaction by providing better service and support.

Methods of Continuous Improvement

There are several methods of continuous improvement that can be used to optimize conditionnement sur palette operations. Some of these include:

- Kaizen events: These events provide a framework for continuous improvement and encourage employee participation.

- Lean manufacturing: This approach focuses on eliminating waste and improving efficiency.

- Six Sigma: This approach focuses on improving the quality of processes and reducing defects.

Conditionnement Sur Palette Image Gallery

What is conditionnement sur palette?

+Conditionnement sur palette refers to the process of preparing and packaging goods on pallets for shipping and storage.

Why is optimizing conditionnement sur palette important?

+Optimizing conditionnement sur palette can help businesses reduce costs, improve efficiency, and enhance customer satisfaction.

What are some ways to optimize conditionnement sur palette?

+Some ways to optimize conditionnement sur palette include implementing a palletization strategy, investing in automation technology, implementing a warehouse management system, providing training and development opportunities, and continuous improvement.

By implementing these strategies, businesses can optimize their conditionnement sur palette operations, reducing costs, improving efficiency, and enhancing customer satisfaction. Remember to continuously evaluate and improve your processes to stay competitive and adapt to changing market conditions.