Intro

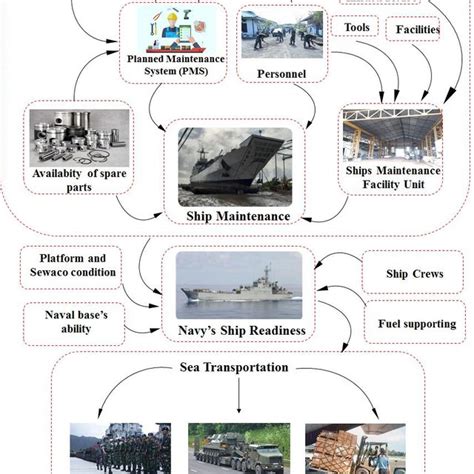

Naval warships face a critical issue with faulty welds, compromising structural integrity and posing safety risks. The growing concern highlights defects in shipbuilding processes, corrosion, and inadequate inspection methods. Learn about the causes, consequences, and potential solutions to address this pressing problem affecting naval fleet reliability and national security.

The United States Navy's warship fleet is facing a growing concern that threatens to compromise its effectiveness in combat: faulty welds. This issue has been plaguing the Navy for years, and it's not just a minor problem. Faulty welds can lead to structural weaknesses, decreased performance, and even catastrophic failures, putting the lives of sailors and the success of missions at risk.

The problem is not limited to a specific class of ships or a particular type of weld. It's a widespread issue that has been reported on various vessels, including aircraft carriers, submarines, and destroyers. The cause of the problem is multifaceted, involving a combination of factors such as inadequate training, poor quality control, and the increasing complexity of modern warship design.

As the Navy continues to push the boundaries of shipbuilding technology, the demands on welders and inspectors have increased exponentially. Modern warships are built with advanced materials and complex systems, requiring welders to possess specialized skills and knowledge. However, the Navy's welding program has struggled to keep pace with these demands, leading to a shortage of qualified welders and inspectors.

The consequences of faulty welds can be severe. In 2019, the Navy's 7th Fleet reported that several of its warships had been forced to return to port due to welding defects. The problem was so widespread that it led to a Congressional hearing, with lawmakers calling for increased funding to address the issue.

In response to the growing concern, the Navy has implemented several measures to improve the quality of its welding program. These measures include increased training for welders and inspectors, improved quality control procedures, and the implementation of new technologies to detect welding defects.

Causes of Faulty Welds in Navy Warships

Faulty welds in Navy warships can be attributed to several factors, including:

-

Inadequate Training

Welders and inspectors require specialized training to work on complex warship systems. However, the Navy's welding program has struggled to provide adequate training, leading to a shortage of qualified personnel.

-

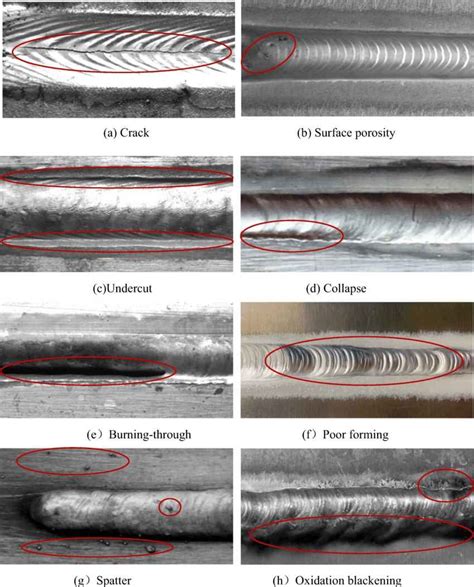

Poor Quality Control

The Navy's quality control procedures have been criticized for being inadequate. Inspectors may not have the necessary training or experience to detect welding defects, and the use of automated inspection systems is not yet widespread.

-

Increasing Complexity of Warship Design

Modern warships are built with advanced materials and complex systems, requiring welders to possess specialized skills and knowledge. However, the Navy's welding program has struggled to keep pace with these demands.

-

Contractor Oversight

The Navy relies heavily on contractors to build and repair its warships. However, contractor oversight has been criticized for being inadequate, leading to a lack of accountability and a increased risk of faulty welds.

Consequences of Faulty Welds

The consequences of faulty welds can be severe, including:

-

Structural Weaknesses

Faulty welds can lead to structural weaknesses, compromising the integrity of the ship's hull and superstructure.

-

Decreased Performance

Faulty welds can also lead to decreased performance, as the ship's systems and equipment may not function properly.

-

Catastrophic Failures

In extreme cases, faulty welds can lead to catastrophic failures, putting the lives of sailors and the success of missions at risk.

Solutions to the Problem

To address the growing concern of faulty welds, the Navy has implemented several measures, including:

-

Increased Training for Welders and Inspectors

The Navy has increased training for welders and inspectors, providing them with the specialized skills and knowledge required to work on complex warship systems.

-

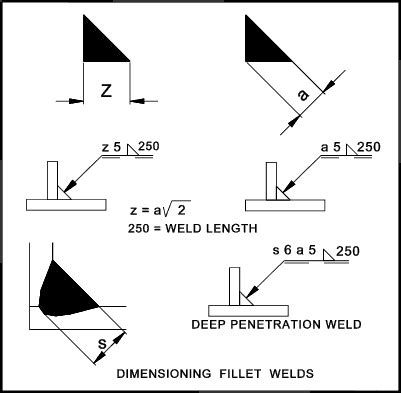

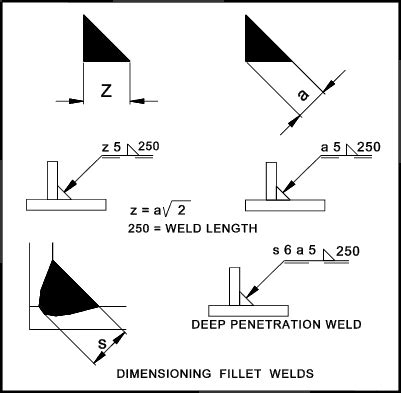

Improved Quality Control Procedures

The Navy has improved its quality control procedures, including the use of automated inspection systems and increased oversight of contractors.

-

Implementation of New Technologies

The Navy has implemented new technologies to detect welding defects, including the use of advanced sensors and machine learning algorithms.

Gallery of Faulty Welds in Navy Warships

Faulty Welds in Navy Warships

Frequently Asked Questions

What is the cause of faulty welds in Navy warships?

+Faulty welds in Navy warships can be attributed to several factors, including inadequate training, poor quality control, and the increasing complexity of warship design.

What are the consequences of faulty welds in Navy warships?

+The consequences of faulty welds can be severe, including structural weaknesses, decreased performance, and even catastrophic failures.

What measures is the Navy taking to address the issue of faulty welds?

+The Navy is taking several measures to address the issue, including increased training for welders and inspectors, improved quality control procedures, and the implementation of new technologies to detect welding defects.

We hope this article has provided valuable insights into the issue of faulty welds in Navy warships. If you have any questions or comments, please don't hesitate to reach out.