Intro

Ensure a smooth PCS move with these 7 essential tips for Fort Bliss maintenance success. From scheduling inspections to understanding regulations, our expert guide covers everything you need to know to pass with flying colors. Learn how to ace your Fort Bliss housing maintenance, avoid fines, and ensure a hassle-free experience.

Effective maintenance is crucial for the success of any military installation, and Fort Bliss is no exception. Located in El Paso, Texas, Fort Bliss is a United States Army post that serves as the home of the 1st Armored Division and the 32nd Army Air and Missile Defense Command, among other units. To ensure the smooth operation of the post's facilities and equipment, maintenance personnel must be well-trained, well-equipped, and well-organized.

In this article, we will discuss seven tips for Fort Bliss maintenance success. By following these tips, maintenance personnel can help ensure that the post's facilities and equipment are always in good working order, and that the soldiers and civilians who work and live on the post have a safe and healthy environment in which to work and live.

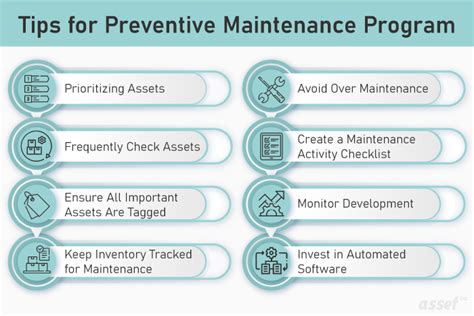

Tip #1: Develop a Preventive Maintenance Program

A preventive maintenance program is a proactive approach to maintenance that involves regularly scheduled maintenance activities to prevent equipment failures and reduce downtime. By developing a preventive maintenance program, maintenance personnel at Fort Bliss can help ensure that the post's facilities and equipment are always in good working order, and that the risk of equipment failures is minimized.

Key Elements of a Preventive Maintenance Program

- Regularly scheduled maintenance activities

- Inspections and testing of equipment

- Replacement of worn or damaged parts

- Lubrication and cleaning of equipment

- Training and certification of maintenance personnel

Tip #2: Use a Computerized Maintenance Management System (CMMS)

A CMMS is a software program that helps maintenance personnel manage and track maintenance activities, including work orders, inventory, and equipment history. By using a CMMS, maintenance personnel at Fort Bliss can streamline their maintenance operations, reduce paperwork, and improve communication.

Key Benefits of a CMMS

- Improved tracking and management of maintenance activities

- Reduced paperwork and administrative tasks

- Improved communication and collaboration among maintenance personnel

- Enhanced reporting and analysis capabilities

Tip #3: Train and Certify Maintenance Personnel

Well-trained and certified maintenance personnel are essential for effective maintenance operations. By providing ongoing training and certification programs, maintenance personnel at Fort Bliss can stay up-to-date with the latest maintenance techniques and technologies, and ensure that they have the skills and knowledge needed to perform their jobs safely and effectively.

Key Elements of a Training and Certification Program

- Classroom and on-the-job training

- Certification programs for maintenance personnel

- Continuing education and professional development opportunities

- Mentorship and coaching programs

Tip #4: Conduct Regular Inspections and Testing

Regular inspections and testing are critical components of a preventive maintenance program. By conducting regular inspections and testing, maintenance personnel at Fort Bliss can identify potential equipment failures and take corrective action before a failure occurs.

Key Elements of a Regular Inspection and Testing Program

- Regularly scheduled inspections and testing

- Use of checklists and inspection forms

- Documentation of inspection and testing results

- Corrective action planning and implementation

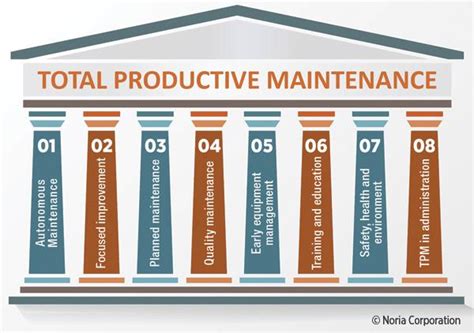

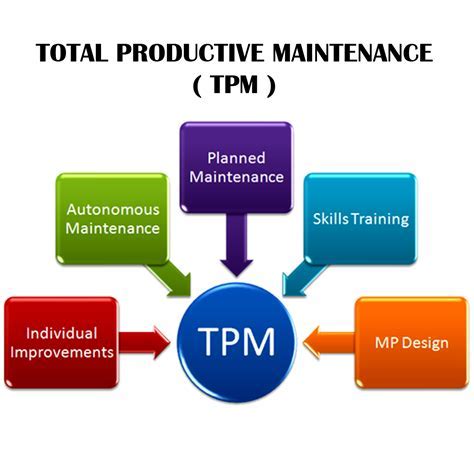

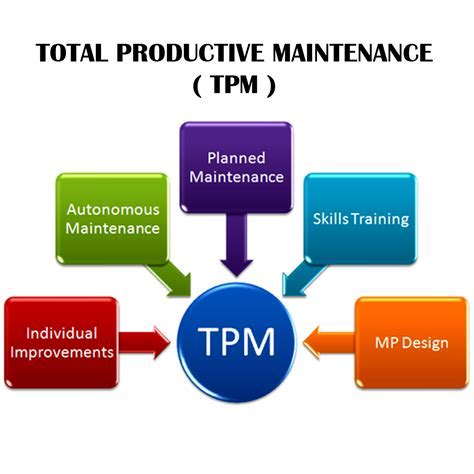

Tip #5: Use Total Productive Maintenance (TPM) Techniques

TPM is a maintenance strategy that involves employees in maintenance activities and empowers them to take ownership of equipment maintenance. By using TPM techniques, maintenance personnel at Fort Bliss can improve equipment reliability, reduce downtime, and increase overall productivity.

Key Elements of a TPM Program

- Employee empowerment and involvement

- Autonomous maintenance activities

- Planned maintenance activities

- Performance measurement and feedback

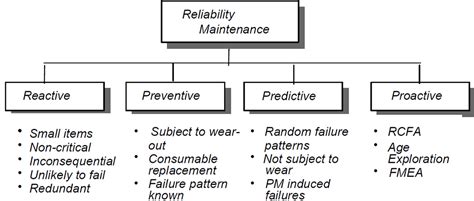

Tip #6: Implement a Reliability-Centered Maintenance (RCM) Program

RCM is a maintenance strategy that focuses on identifying and addressing the root causes of equipment failures. By implementing an RCM program, maintenance personnel at Fort Bliss can improve equipment reliability, reduce downtime, and increase overall productivity.

Key Elements of an RCM Program

- Identification of equipment failure modes

- Analysis of failure modes and effects

- Development of maintenance strategies

- Implementation and evaluation of maintenance strategies

Tip #7: Continuously Monitor and Evaluate Maintenance Operations

Continuous monitoring and evaluation are critical components of a successful maintenance program. By regularly monitoring and evaluating maintenance operations, maintenance personnel at Fort Bliss can identify areas for improvement, measure the effectiveness of maintenance activities, and make data-driven decisions.

Key Elements of a Continuous Monitoring and Evaluation Program

- Regularly scheduled monitoring and evaluation activities

- Use of performance metrics and key performance indicators (KPIs)

- Analysis and reporting of maintenance data

- Continuous improvement planning and implementation

Fort Bliss Maintenance Image Gallery

What is the importance of preventive maintenance at Fort Bliss?

+Preventive maintenance is critical at Fort Bliss because it helps to prevent equipment failures, reduce downtime, and ensure that the post's facilities and equipment are always in good working order.

How can maintenance personnel at Fort Bliss improve their skills and knowledge?

+Maintenance personnel at Fort Bliss can improve their skills and knowledge by participating in ongoing training and certification programs, attending workshops and conferences, and seeking mentorship and coaching from experienced maintenance personnel.

What is the role of TPM in Fort Bliss maintenance operations?

+TPM plays a critical role in Fort Bliss maintenance operations by empowering employees to take ownership of equipment maintenance, improving equipment reliability, and reducing downtime.

We hope this article has provided valuable insights and tips for Fort Bliss maintenance success. By following these tips and best practices, maintenance personnel at Fort Bliss can help ensure that the post's facilities and equipment are always in good working order, and that the soldiers and civilians who work and live on the post have a safe and healthy environment in which to work and live.