Intro

Unlock the full potential of your Lincoln Power MIG welder with these 7 expert tips. Master the art of MIG welding and achieve professional-grade results with advice on settings, technique, and safety. Improve your weld quality, increase efficiency, and take your fabrication skills to the next level with Lincoln Power MIG mastery.

Mastering the Lincoln Power MIG is a crucial step for any welder looking to improve their skills and produce high-quality welds. The Lincoln Power MIG is a versatile and reliable welding machine that can be used for a variety of applications, from automotive repair to construction. In this article, we will provide you with 7 tips for mastering the Lincoln Power MIG, including how to properly set up and maintain the machine, how to adjust the welding parameters, and how to troubleshoot common issues.

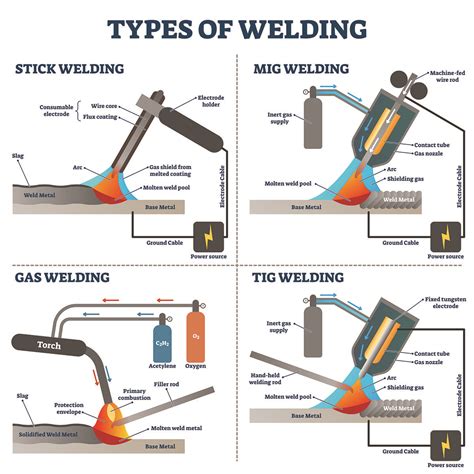

Understanding the Lincoln Power MIG

Before we dive into the tips for mastering the Lincoln Power MIG, it's essential to understand the basics of the machine. The Lincoln Power MIG is a MIG (GMAW) welder that uses a continuous wire feed to produce a high-quality weld. The machine is equipped with a variety of features, including a digital display, adjustable welding parameters, and a built-in wire feeder.

Tip 1: Proper Setup and Maintenance

Proper setup and maintenance are crucial for ensuring the Lincoln Power MIG runs smoothly and produces high-quality welds. Here are a few things to check:

- Make sure the machine is properly grounded and plugged into a suitable power source.

- Check the wire feeder for any blockages or kinks.

- Ensure the welding gun is properly connected to the machine and the wire feeder is set to the correct tension.

- Regularly clean the machine and welding gun to prevent dirt and debris from building up.

Benefits of Proper Setup and Maintenance

Proper setup and maintenance can help prevent common issues such as poor weld quality, wire feed problems, and machine failure. Regular maintenance can also help extend the life of the machine and reduce downtime.

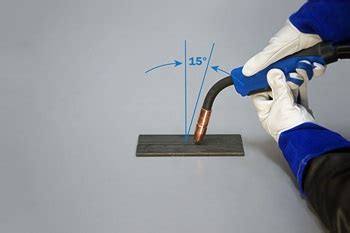

Tip 2: Adjusting Welding Parameters

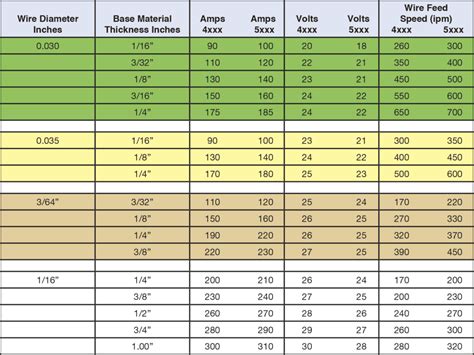

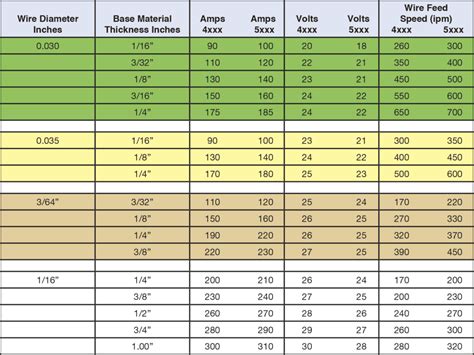

Adjusting the welding parameters is critical for producing high-quality welds with the Lincoln Power MIG. Here are a few things to consider:

- Voltage: The voltage setting will depend on the thickness of the material being welded. A higher voltage setting is typically required for thicker materials.

- Wire feed speed: The wire feed speed will also depend on the thickness of the material being welded. A faster wire feed speed is typically required for thicker materials.

- Shielding gas: The type and flow rate of shielding gas will depend on the material being welded and the desired weld quality.

Benefits of Adjusting Welding Parameters

Adjusting the welding parameters can help improve weld quality, reduce porosity, and increase productivity. By adjusting the parameters to match the specific welding application, welders can produce high-quality welds with ease.

Tip 3: Troubleshooting Common Issues

Troubleshooting common issues is essential for minimizing downtime and maximizing productivity. Here are a few common issues and their solutions:

- Poor weld quality: Check the welding parameters, wire feed speed, and shielding gas flow rate.

- Wire feed problems: Check the wire feeder for blockages or kinks, and ensure the wire is properly seated in the gun.

- Machine failure: Check the power source, ensure the machine is properly grounded, and consult the user manual for troubleshooting guides.

Benefits of Troubleshooting Common Issues

Troubleshooting common issues can help minimize downtime, reduce waste, and increase productivity. By identifying and resolving issues quickly, welders can produce high-quality welds and meet deadlines.

Tip 4: Practice and Training

Practice and training are essential for mastering the Lincoln Power MIG. Here are a few tips for improving your skills:

- Start with simple welds and gradually move on to more complex projects.

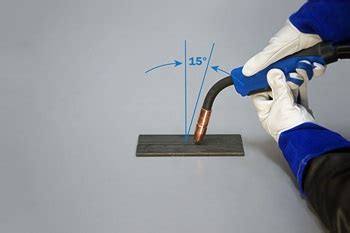

- Practice different welding techniques, such as push and pull welding.

- Take online courses or attend workshops to learn new skills and stay up-to-date with the latest welding technologies.

Benefits of Practice and Training

Practice and training can help improve weld quality, increase productivity, and reduce downtime. By continuously practicing and learning new skills, welders can stay up-to-date with the latest welding technologies and produce high-quality welds.

Tip 5: Using the Correct Wire

Using the correct wire is critical for producing high-quality welds with the Lincoln Power MIG. Here are a few things to consider:

- Material: The wire should match the material being welded.

- Thickness: The wire thickness should match the thickness of the material being welded.

- Type: The wire type should match the welding application. For example, a solid wire is typically used for welding steel, while a flux-cored wire is typically used for welding aluminum.

Benefits of Using the Correct Wire

Using the correct wire can help improve weld quality, reduce porosity, and increase productivity. By using the correct wire, welders can produce high-quality welds with ease.

Tip 6: Maintaining the Welding Gun

Maintaining the welding gun is essential for ensuring the Lincoln Power MIG runs smoothly and produces high-quality welds. Here are a few things to check:

- Nozzle: The nozzle should be clean and free of debris.

- Contact tip: The contact tip should be clean and free of debris.

- Wire feeder: The wire feeder should be clean and free of debris.

Benefits of Maintaining the Welding Gun

Maintaining the welding gun can help improve weld quality, reduce downtime, and increase productivity. By regularly cleaning and maintaining the welding gun, welders can produce high-quality welds with ease.

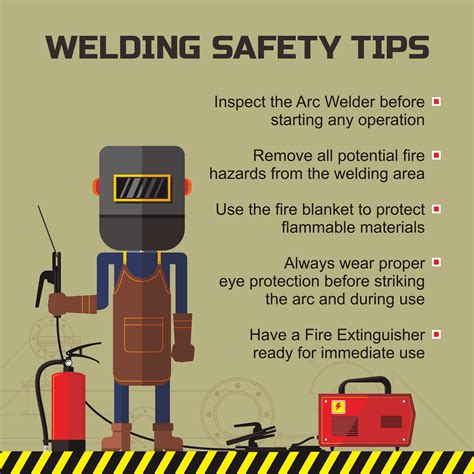

Tip 7: Staying Safe

Staying safe is essential when working with the Lincoln Power MIG. Here are a few things to consider:

- Personal protective equipment (PPE): Wear PPE, such as a welding helmet, gloves, and safety glasses, to protect yourself from sparks and debris.

- Ventilation: Ensure good ventilation in the work area to prevent inhalation of fumes and particles.

- Electrical safety: Ensure the machine is properly grounded and plugged into a suitable power source.

Benefits of Staying Safe

Staying safe can help prevent injuries, reduce downtime, and increase productivity. By taking the necessary safety precautions, welders can produce high-quality welds while minimizing the risk of injury.

Lincoln Power MIG Image Gallery

What is the Lincoln Power MIG?

+The Lincoln Power MIG is a MIG (GMAW) welder that uses a continuous wire feed to produce a high-quality weld.

How do I properly set up the Lincoln Power MIG?

+Make sure the machine is properly grounded, plugged into a suitable power source, and the wire feeder is set to the correct tension.

What are the benefits of using the correct wire?

+Using the correct wire can help improve weld quality, reduce porosity, and increase productivity.

We hope you found these tips for mastering the Lincoln Power MIG helpful. Remember to always follow safety guidelines and best practices when working with any welding machine. Happy welding!