Intro

Optimize your pressure washers performance with the right jet nozzle. Learn how to choose the official jet nozzle for your needs with our expert guide. Discover the 5 key factors to consider, including flow rate, pressure, and spray pattern, to ensure a perfect match for your equipment and maximize cleaning efficiency and effectiveness.

Choosing the right jet nozzle can be a daunting task, especially with the numerous options available in the market. A jet nozzle is a crucial component of a jet pump or a sprinkler system, and its selection can significantly impact the performance and efficiency of the entire system. In this article, we will explore the key factors to consider when selecting the official jet nozzle for your specific application.

Understanding Jet Nozzles

A jet nozzle is a type of nozzle that is designed to produce a high-velocity jet of fluid, typically water or air. It is commonly used in irrigation systems, fire protection systems, and industrial processes. The nozzle's design and configuration determine the shape and size of the jet, which in turn affects the distribution of the fluid.

Key Considerations for Choosing a Jet Nozzle

When selecting a jet nozzle, there are several factors to consider to ensure that you choose the right one for your specific application. Here are five key considerations to keep in mind:

- Flow Rate and Pressure The flow rate and pressure of the fluid being discharged are critical factors in selecting a jet nozzle. The nozzle must be designed to handle the desired flow rate and pressure to ensure optimal performance. A nozzle with a higher flow rate and pressure rating than required can lead to energy waste and increased costs.

- Jet Pattern and Distribution The jet pattern and distribution are crucial in determining the effectiveness of the nozzle. Different applications require different jet patterns, such as a narrow jet for irrigation or a wide fan jet for fire protection. The nozzle's design and configuration will determine the shape and size of the jet.

- Nozzle Material and Durability The material and durability of the nozzle are essential considerations, especially in harsh environments. The nozzle must be able to withstand the corrosive and erosive effects of the fluid being discharged. Common materials used for jet nozzles include brass, stainless steel, and PVC.

- Installation and Maintenance The installation and maintenance requirements of the nozzle should also be considered. A nozzle that is easy to install and maintain can save time and costs in the long run. Consider the type of connections required and the accessibility of the nozzle for maintenance and repair.

- Certifications and Compliance Finally, ensure that the nozzle meets the necessary certifications and compliances for your specific application. For example, a nozzle used in a fire protection system must meet the relevant standards and regulations, such as NFPA 13.

Types of Jet Nozzles

There are several types of jet nozzles available, each with its unique characteristics and applications. Some common types of jet nozzles include:

- Fan Jet Nozzles: These nozzles produce a wide fan-shaped jet and are commonly used in irrigation and fire protection systems.

- Narrow Jet Nozzles: These nozzles produce a narrow jet and are often used in industrial processes, such as cutting and cleaning.

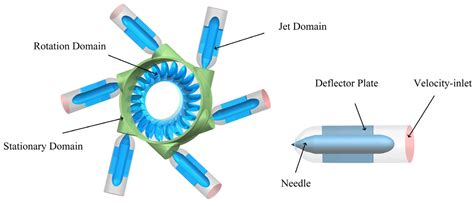

- Deflector Jet Nozzles: These nozzles produce a deflected jet and are used in applications where the jet needs to be directed at a specific angle.

- Rotating Jet Nozzles: These nozzles produce a rotating jet and are used in applications where a wide coverage area is required.

Benefits of Choosing the Right Jet Nozzle

Choosing the right jet nozzle can have significant benefits, including:

- Improved Efficiency: A nozzle that is designed for the specific application can improve the efficiency of the system, reducing energy costs and increasing productivity.

- Increased Accuracy: A nozzle that produces a consistent and accurate jet can improve the effectiveness of the system, reducing waste and improving outcomes.

- Reduced Maintenance: A nozzle that is easy to install and maintain can reduce downtime and maintenance costs.

- Compliance with Regulations: A nozzle that meets the necessary certifications and compliances can ensure that the system meets the relevant standards and regulations.

Conclusion

Choosing the official jet nozzle for your specific application requires careful consideration of several factors, including flow rate and pressure, jet pattern and distribution, nozzle material and durability, installation and maintenance, and certifications and compliance. By considering these factors and selecting the right nozzle, you can improve the efficiency, accuracy, and effectiveness of your system, while also reducing maintenance costs and ensuring compliance with regulations.

Gallery of Jet Nozzle Images

Jet Nozzle Image Gallery

What is a jet nozzle?

+A jet nozzle is a type of nozzle that is designed to produce a high-velocity jet of fluid, typically water or air.

What are the key considerations for choosing a jet nozzle?

+The key considerations for choosing a jet nozzle include flow rate and pressure, jet pattern and distribution, nozzle material and durability, installation and maintenance, and certifications and compliance.

What are the benefits of choosing the right jet nozzle?

+The benefits of choosing the right jet nozzle include improved efficiency, increased accuracy, reduced maintenance, and compliance with regulations.