Intro

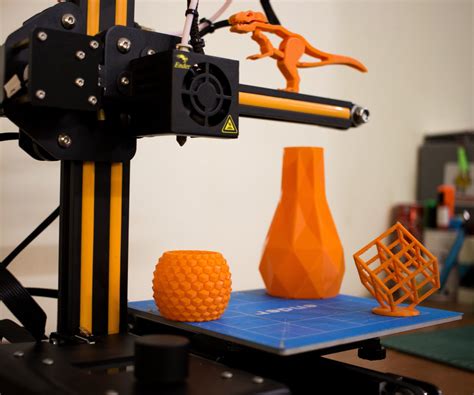

Discover stunning printable 3D printer models, featuring intricate designs, STL files, and DIY tutorials, perfect for makers and hobbyists, with free downloads and custom 3D printing options.

The world of 3D printing has revolutionized the way we create and manufacture objects. With the rise of affordable and accessible 3D printing technology, hobbyists, makers, and professionals alike can now bring their ideas to life. One of the most exciting aspects of 3D printing is the ability to create complex and intricate designs that would be impossible to produce with traditional manufacturing methods. In this article, we will delve into the world of printable 3D printer models, exploring the benefits, types, and applications of these amazing creations.

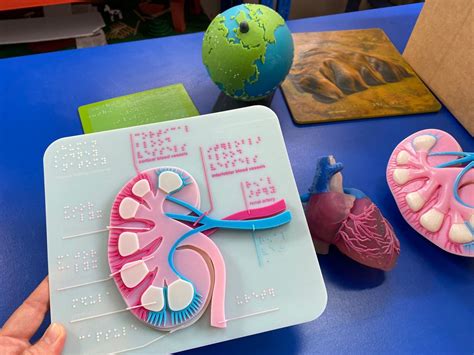

The importance of printable 3D printer models cannot be overstated. These models have the potential to transform industries such as healthcare, education, and manufacturing, among others. For instance, 3D printed prosthetics and implants can be customized to fit individual patients, improving their quality of life. Similarly, 3D printed educational models can help students better understand complex concepts, making learning more engaging and effective. As the technology continues to evolve, we can expect to see even more innovative applications of printable 3D printer models.

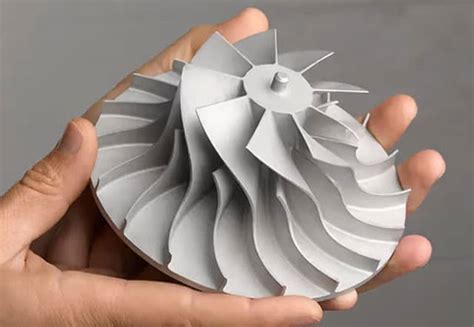

The versatility of printable 3D printer models is another significant advantage. These models can be designed to serve a wide range of purposes, from functional prototypes to artistic sculptures. With the use of various materials, such as plastics, metals, and ceramics, 3D printed models can be tailored to meet specific requirements, including strength, durability, and aesthetics. Furthermore, the ability to print models with intricate details and complex geometries has opened up new possibilities for designers, engineers, and artists.

Introduction to Printable 3D Printer Models

Types of Printable 3D Printer Models

There are several types of printable 3D printer models, each with its own unique characteristics and applications. Some of the most common types include: * Functional models: These models are designed to serve a specific purpose, such as prototypes, tools, or machine parts. * Artistic models: These models are created for aesthetic purposes, such as sculptures, jewelry, or decorative items. * Educational models: These models are designed to help students learn complex concepts, such as anatomy, physics, or engineering. * Architectural models: These models are used to visualize and communicate building designs, allowing architects and clients to explore and refine their ideas.Benefits of Printable 3D Printer Models

Applications of Printable 3D Printer Models

The applications of printable 3D printer models are diverse and widespread. Some of the most significant uses include: * Healthcare: 3D printed models are used in medical research, education, and patient care, including the creation of customized prosthetics, implants, and surgical guides. * Education: 3D printed models are used to teach complex concepts, such as anatomy, physics, and engineering, making learning more engaging and effective. * Manufacturing: 3D printed models are used to create prototypes, tools, and machine parts, reducing the time and cost associated with traditional manufacturing methods. * Architecture: 3D printed models are used to visualize and communicate building designs, allowing architects and clients to explore and refine their ideas.Designing Printable 3D Printer Models

Tools and Software for Designing Printable 3D Printer Models

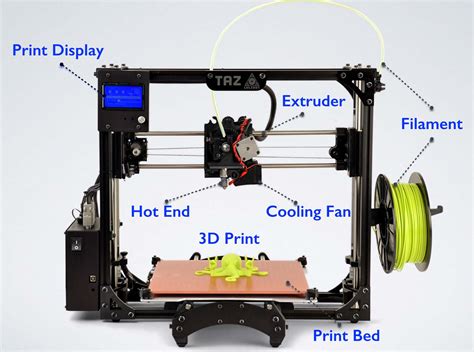

There are several tools and software available for designing printable 3D printer models, including: * CAD software: Programs such as Autodesk Inventor, SolidWorks, and Fusion 360 allow designers to create complex digital models. * 3D modeling software: Programs such as Blender, Maya, and 3ds Max enable designers to create detailed and realistic models. * Slicing software: Programs such as Cura, Slic3r, and Simplify3D allow designers to prepare their models for printing.Printing Printable 3D Printer Models

Types of 3D Printing Technologies

There are several types of 3D printing technologies, each with its own unique characteristics and applications. Some of the most common types include: * Fused Deposition Modeling (FDM): This technology uses melted plastic to create objects layer by layer. * Stereolithography (SLA): This technology uses a laser to cure liquid resin, creating highly detailed and accurate objects. * Selective Laser Sintering (SLS): This technology uses a laser to fuse together particles of a powdered material, creating strong and durable objects.Printable 3D Printer Models Image Gallery

What is the purpose of printable 3D printer models?

+Printable 3D printer models are digital files that contain the instructions for a 3D printer to create a physical object. These models can be used for a wide range of purposes, including prototyping, education, and manufacturing.

What are the benefits of using printable 3D printer models?

+The benefits of using printable 3D printer models include rapid prototyping, increased accuracy, customization, and cost-effectiveness. These models can also be used to create complex and intricate designs that would be impossible to produce with traditional manufacturing methods.

What types of materials can be used for 3D printing?

+A wide range of materials can be used for 3D printing, including plastics, metals, ceramics, and glass. The choice of material depends on the specific application and the desired properties of the final product.

What is the future of printable 3D printer models?

+The future of printable 3D printer models is exciting and rapidly evolving. As the technology continues to improve, we can expect to see even more innovative applications of 3D printing, including the creation of complex and customized products, such as prosthetics, implants, and dental models.

How can I get started with designing and printing my own 3D models?

+To get started with designing and printing your own 3D models, you will need to invest in a 3D printer and learn how to use CAD software or other 3D modeling tools. There are many online resources and tutorials available to help you learn the basics of 3D printing and design.

In conclusion, printable 3D printer models have the potential to transform industries and revolutionize the way we create and manufacture objects. With the ability to design and print complex and customized products, 3D printing is an exciting and rapidly evolving field that is sure to continue to grow and develop in the coming years. Whether you are a hobbyist, a professional, or simply someone who is interested in learning more about 3D printing, there has never been a better time to get involved and explore the possibilities of this amazing technology. So why not start designing and printing your own 3D models today and see what incredible things you can create? Share your experiences and thoughts on printable 3D printer models in the comments below, and don't forget to share this article with anyone who might be interested in learning more about this exciting topic.