Intro

Discover the causes of reduced propulsion power in vehicles and learn how to resolve the issue. From faulty fuel injectors to clogged air filters, explore the common culprits behind decreased engine performance. Get expert solutions and DIY fixes to boost horsepower, improve fuel efficiency, and restore your vehicles optimal propulsion power.

Reduced propulsion power can significantly impact the performance and efficiency of various systems, including vehicles, machinery, and even entire industries. Understanding the causes and solutions for reduced propulsion power is crucial for optimizing operations, reducing costs, and enhancing overall productivity.

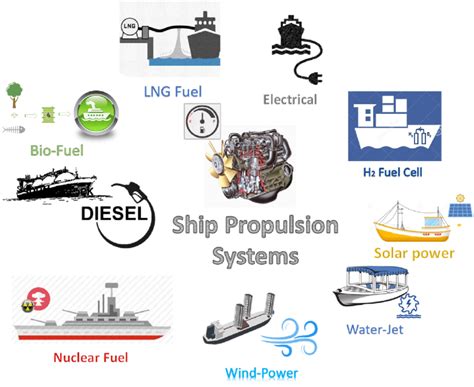

Propulsion power is the energy generated by a system to produce motion or thrust. In vehicles, for example, propulsion power is the force that propels the vehicle forward, overcoming resistance from factors like friction, air resistance, and gravity. Reduced propulsion power can result from a range of factors, including mechanical issues, inefficient energy conversion, and external conditions.

Causes of Reduced Propulsion Power

There are several causes of reduced propulsion power, including:

1. Mechanical Issues

Mechanical issues, such as worn-out or damaged components, can significantly reduce propulsion power. In vehicles, for example, a faulty transmission or a malfunctioning engine can lead to reduced propulsion power.

2. Inefficient Energy Conversion

Inefficient energy conversion can also lead to reduced propulsion power. In systems that rely on energy conversion, such as electric motors, inefficient energy conversion can result in reduced propulsion power.

3. External Conditions

External conditions, such as weather or terrain, can also impact propulsion power. For example, driving a vehicle in hilly or mountainous terrain can reduce propulsion power due to the increased resistance.

Internal Factors

Internal factors, such as mechanical friction and energy losses, can also contribute to reduced propulsion power. In vehicles, for example, mechanical friction in the engine and transmission can reduce propulsion power.

External Factors

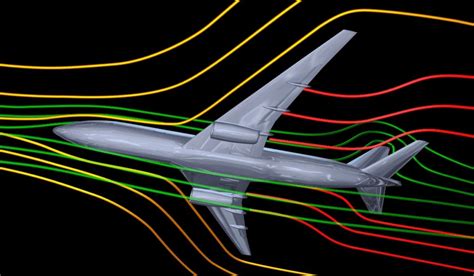

External factors, such as air resistance and rolling resistance, can also impact propulsion power. In vehicles, for example, air resistance can reduce propulsion power, particularly at high speeds.

Solutions for Reduced Propulsion Power

Fortunately, there are several solutions for reduced propulsion power, including:

1. Regular Maintenance

Regular maintenance is crucial for optimizing propulsion power. In vehicles, for example, regular maintenance, such as oil changes and tire rotations, can help ensure optimal propulsion power.

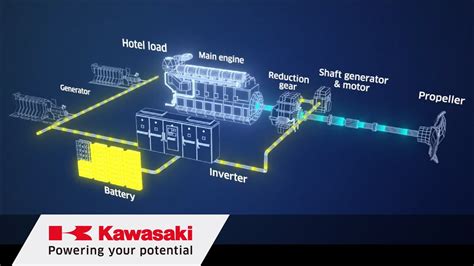

2. Energy-Efficient Systems

Energy-efficient systems, such as electric motors and advanced transmission systems, can also help optimize propulsion power. These systems can reduce energy losses and improve energy conversion efficiency.

3. Aerodynamic Design

Aerodynamic design can also help reduce air resistance and optimize propulsion power. In vehicles, for example, aerodynamic design can improve fuel efficiency and reduce emissions.

Advanced Materials

Advanced materials, such as lightweight composites and high-strength alloys, can also help optimize propulsion power. These materials can reduce weight and improve structural integrity, leading to improved propulsion power.

Optimization Techniques

Optimization techniques, such as computer simulations and data analysis, can also help optimize propulsion power. These techniques can help identify areas of improvement and optimize system performance.

Benefits of Optimizing Propulsion Power

Optimizing propulsion power can have numerous benefits, including:

- Improved efficiency

- Reduced costs

- Increased productivity

- Enhanced performance

- Reduced emissions

Conclusion

Reduced propulsion power can have significant impacts on system performance and efficiency. By understanding the causes and solutions for reduced propulsion power, individuals and organizations can take steps to optimize propulsion power and improve overall performance. Whether through regular maintenance, energy-efficient systems, or advanced materials, optimizing propulsion power can have numerous benefits.

Gallery of Propulsion Power Solutions

What are the causes of reduced propulsion power?

+The causes of reduced propulsion power include mechanical issues, inefficient energy conversion, and external conditions, such as weather or terrain.

How can I optimize propulsion power?

+You can optimize propulsion power by performing regular maintenance, using energy-efficient systems, and incorporating advanced materials and optimization techniques.

What are the benefits of optimizing propulsion power?

+The benefits of optimizing propulsion power include improved efficiency, reduced costs, increased productivity, enhanced performance, and reduced emissions.