Intro

Discover the latest advancements in naval architecture with Proving Ground Hull Design And Testing. Learn how model testing, computational fluid dynamics, and full-scale trials converge to optimize hull design, reduce drag, and enhance vessel performance. Explore the intersection of innovation, experimentation, and expertise in shipbuilding and maritime engineering.

Proving ground hull design and testing are crucial stages in the development of a vehicle, particularly in the automotive and aerospace industries. A proving ground is a controlled environment where vehicles are tested and evaluated to ensure they meet specific performance, safety, and durability standards. In this article, we will delve into the importance of proving ground hull design and testing, its benefits, and the various stages involved in the process.

A well-designed hull is essential for a vehicle's performance, safety, and overall efficiency. The hull design affects the vehicle's aerodynamics, weight distribution, and structural integrity. A proving ground allows manufacturers to test and refine their hull designs, ensuring that they meet the required standards and regulations. This stage is critical in identifying and addressing potential issues before the vehicle enters mass production.

Benefits of Proving Ground Hull Design and Testing

Proving ground hull design and testing offer numerous benefits, including:

- Improved performance: Testing and refining the hull design enables manufacturers to optimize the vehicle's performance, handling, and stability.

- Enhanced safety: Identifying and addressing potential safety issues during the testing phase ensures that the vehicle meets the required safety standards.

- Increased efficiency: A well-designed hull can improve the vehicle's aerodynamics, reducing wind resistance and improving fuel efficiency.

- Reduced production costs: Detecting and fixing issues during the testing phase can save manufacturers significant costs and time in the long run.

Stages Involved in Proving Ground Hull Design and Testing

The proving ground hull design and testing process involves several stages, including:

- Design and simulation: The hull design is created using computer-aided design (CAD) software and simulated using computational fluid dynamics (CFD) and finite element analysis (FEA) tools.

- Prototype development: A prototype of the vehicle is built, incorporating the designed hull.

- Testing and evaluation: The prototype is tested on a proving ground, where its performance, safety, and durability are evaluated.

- Refining and iterating: Based on the test results, the hull design is refined and iterated until it meets the required standards.

Technologies Used in Proving Ground Hull Design and Testing

Several technologies are employed in proving ground hull design and testing, including:

- Computer-aided design (CAD) software: Used to create and simulate the hull design.

- Computational fluid dynamics (CFD) tools: Used to analyze the aerodynamics and fluid dynamics of the hull.

- Finite element analysis (FEA) tools: Used to analyze the structural integrity and stress distribution of the hull.

- Sensors and data acquisition systems: Used to collect data during testing and evaluation.

Real-World Applications of Proving Ground Hull Design and Testing

Proving ground hull design and testing have numerous real-world applications, including:

- Automotive industry: Used to develop and test new vehicle models, ensuring they meet performance, safety, and regulatory standards.

- Aerospace industry: Used to develop and test aircraft and spacecraft, ensuring they meet performance, safety, and regulatory standards.

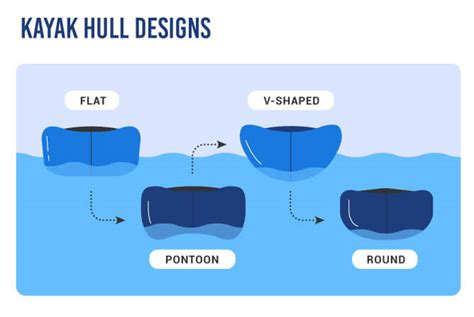

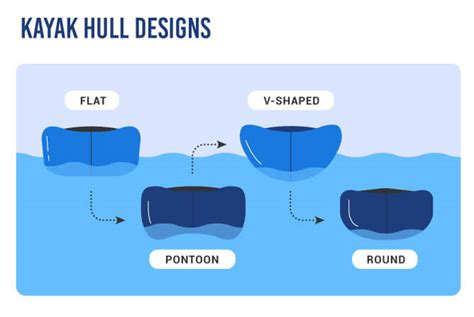

- Marine industry: Used to develop and test boats and ships, ensuring they meet performance, safety, and regulatory standards.

Proving Ground Hull Design and Testing Image Gallery

What is proving ground hull design and testing?

+Proving ground hull design and testing is the process of designing and testing a vehicle's hull to ensure it meets performance, safety, and regulatory standards.

What are the benefits of proving ground hull design and testing?

+The benefits of proving ground hull design and testing include improved performance, enhanced safety, increased efficiency, and reduced production costs.

What technologies are used in proving ground hull design and testing?

+Technologies used in proving ground hull design and testing include computer-aided design (CAD) software, computational fluid dynamics (CFD) tools, finite element analysis (FEA) tools, sensors, and data acquisition systems.