Intro

Discover the best MIG welding gas for stainless steel welding. Learn how to choose the ideal shielding gas mixture for optimal weld quality, penetration, and corrosion resistance. Explore the differences between Argon, Helium, and CO2 gases, and find the perfect blend for your stainless steel welding projects.

Welding stainless steel can be a challenging task, especially when it comes to choosing the right shielding gas. The quality of the weld, the appearance of the weld, and the overall performance of the weld are all dependent on the type of gas used. In this article, we will explore the best MIG welding gas for stainless steel and provide you with a comprehensive guide to help you make an informed decision.

MIG welding, also known as Gas Metal Arc Welding (GMAW), is a popular welding process that uses a continuous wire electrode and an inert shielding gas to protect the arc and molten metal from atmospheric gases. When it comes to welding stainless steel, the choice of shielding gas is critical to prevent porosity, lack of fusion, and other defects.

What is the Best MIG Welding Gas for Stainless Steel?

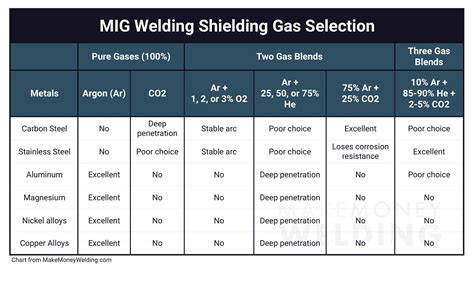

The best MIG welding gas for stainless steel is a tri-mix gas, which is a blend of 90% helium, 7.5% argon, and 2.5% carbon dioxide. This gas mixture provides the optimal balance of weld penetration, arc stability, and surface finish. The helium content in the gas mixture helps to increase the weld penetration and speed, while the argon content helps to stabilize the arc and prevent porosity. The carbon dioxide content helps to improve the weld pool fluidity and reduce the risk of lack of fusion.

Why Use a Tri-Mix Gas for Stainless Steel?

There are several reasons why a tri-mix gas is the best choice for welding stainless steel:

- Improved weld penetration: The helium content in the gas mixture helps to increase the weld penetration, which is critical for welding thick stainless steel sections.

- Increased arc stability: The argon content in the gas mixture helps to stabilize the arc, which reduces the risk of porosity and lack of fusion.

- Better surface finish: The tri-mix gas mixture provides a smooth, even surface finish, which is critical for applications where appearance is important.

- Reduced risk of defects: The tri-mix gas mixture reduces the risk of defects such as porosity, lack of fusion, and weld cracking.

Other Gas Mixtures for Stainless Steel

While a tri-mix gas is the best choice for welding stainless steel, there are other gas mixtures that can be used in certain situations:

- Argon-rich gas mixture: An argon-rich gas mixture (95% argon, 5% carbon dioxide) can be used for welding thin stainless steel sections or for applications where a high-quality surface finish is not critical.

- Helium-rich gas mixture: A helium-rich gas mixture (90% helium, 10% argon) can be used for welding thick stainless steel sections or for applications where high weld penetration is critical.

Factors to Consider When Choosing a MIG Welding Gas

When choosing a MIG welding gas for stainless steel, there are several factors to consider:

- Weld penetration: The gas mixture should provide adequate weld penetration to ensure a strong, reliable weld.

- Arc stability: The gas mixture should provide a stable arc to reduce the risk of porosity and lack of fusion.

- Surface finish: The gas mixture should provide a smooth, even surface finish to meet the requirements of the application.

- Cost: The cost of the gas mixture should be considered, as some gas mixtures may be more expensive than others.

- Availability: The availability of the gas mixture should be considered, as some gas mixtures may be more readily available than others.

Best Practices for MIG Welding Stainless Steel

To ensure high-quality welds when MIG welding stainless steel, follow these best practices:

- Use a tri-mix gas: A tri-mix gas is the best choice for welding stainless steel, as it provides the optimal balance of weld penetration, arc stability, and surface finish.

- Maintain a consistent wire feed speed: A consistent wire feed speed is critical to maintaining a stable arc and ensuring high-quality welds.

- Use a suitable welding technique: The welding technique used should be suitable for the application and the type of stainless steel being welded.

- Keep the welding area clean: The welding area should be kept clean and free of debris to prevent contamination and ensure high-quality welds.

Gallery of MIG Welding Gas for Stainless Steel

MIG Welding Gas for Stainless Steel Gallery

FAQs

What is the best MIG welding gas for stainless steel?

+The best MIG welding gas for stainless steel is a tri-mix gas, which is a blend of 90% helium, 7.5% argon, and 2.5% carbon dioxide.

Why is a tri-mix gas the best choice for welding stainless steel?

+A tri-mix gas provides the optimal balance of weld penetration, arc stability, and surface finish, making it the best choice for welding stainless steel.

What are the factors to consider when choosing a MIG welding gas for stainless steel?

+The factors to consider when choosing a MIG welding gas for stainless steel include weld penetration, arc stability, surface finish, cost, and availability.

By following the guidelines outlined in this article, you can ensure high-quality welds when MIG welding stainless steel. Remember to use a tri-mix gas, maintain a consistent wire feed speed, and keep the welding area clean to prevent contamination. With the right gas mixture and proper techniques, you can achieve strong, reliable welds that meet the requirements of your application.