Intro

Unlock the future of manufacturing with superior joining technologies. Discover how advancements in welding, bonding, and fastening are transforming industries. Learn about innovative techniques, equipment, and materials that improve efficiency, quality, and sustainability. Explore the latest trends and applications in metal fabrication, automotive, aerospace, and more.

The manufacturing industry is constantly evolving, and one key area of innovation is in the development of superior joining technologies. The ability to effectively join different materials and components is crucial in creating complex products, and advancements in this area have the potential to revolutionize the manufacturing process. In this article, we will explore the importance of superior joining technologies and the various methods that are being used to advance manufacturing.

What are Superior Joining Technologies?

Superior joining technologies refer to the various methods and techniques used to join different materials and components together. These technologies are designed to provide strong, reliable, and efficient bonds between different materials, and they are critical in a wide range of manufacturing applications. From the assembly of complex machinery to the production of consumer goods, superior joining technologies play a vital role in ensuring the quality and integrity of the final product.

Types of Superior Joining Technologies

There are several types of superior joining technologies that are commonly used in manufacturing, including:

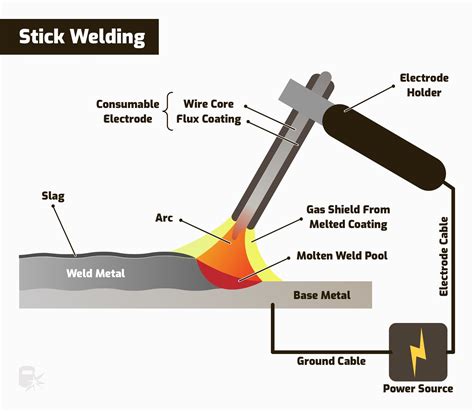

- Welding: a process that uses heat and pressure to join two metal components together.

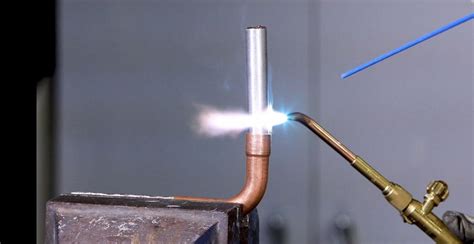

- Brazing: a process that uses a filler material to join two metal components together.

- Soldering: a process that uses a filler material to join two metal components together, typically at a lower temperature than brazing.

- Adhesive bonding: a process that uses adhesives to join two components together.

- Mechanical fastening: a process that uses fasteners, such as screws and rivets, to join two components together.

Advantages of Superior Joining Technologies

Superior joining technologies offer several advantages over traditional joining methods, including:

- Increased strength and durability: Superior joining technologies can provide stronger and more durable bonds between components, resulting in longer product lifetimes and reduced maintenance costs.

- Improved quality and consistency: Superior joining technologies can provide more consistent and higher-quality bonds, resulting in reduced defect rates and improved product reliability.

- Increased efficiency and productivity: Superior joining technologies can be more efficient and productive than traditional joining methods, resulting in reduced production times and costs.

- Greater design flexibility: Superior joining technologies can enable the creation of complex and innovative products that would be difficult or impossible to produce using traditional joining methods.

Applications of Superior Joining Technologies

Superior joining technologies have a wide range of applications in various industries, including:

- Aerospace: Superior joining technologies are used in the production of aircraft and spacecraft, where strong and lightweight bonds are critical.

- Automotive: Superior joining technologies are used in the production of vehicles, where strong and durable bonds are critical for safety and performance.

- Medical devices: Superior joining technologies are used in the production of medical devices, where strong and biocompatible bonds are critical.

- Consumer goods: Superior joining technologies are used in the production of consumer goods, such as electronics and appliances, where strong and durable bonds are critical for performance and reliability.

Challenges and Limitations of Superior Joining Technologies

While superior joining technologies offer several advantages, there are also several challenges and limitations to consider, including:

- Cost and complexity: Superior joining technologies can be more expensive and complex than traditional joining methods, requiring specialized equipment and expertise.

- Material compatibility: Superior joining technologies can be limited by material compatibility issues, where certain materials may not be compatible with certain joining methods.

- Quality control: Superior joining technologies require careful quality control measures to ensure consistent and high-quality bonds.

Future Developments in Superior Joining Technologies

The development of superior joining technologies is an ongoing process, with researchers and manufacturers continually working to improve and expand the range of available technologies. Some potential future developments in superior joining technologies include:

- Advanced welding techniques: New welding techniques, such as laser welding and electron beam welding, offer improved precision and control.

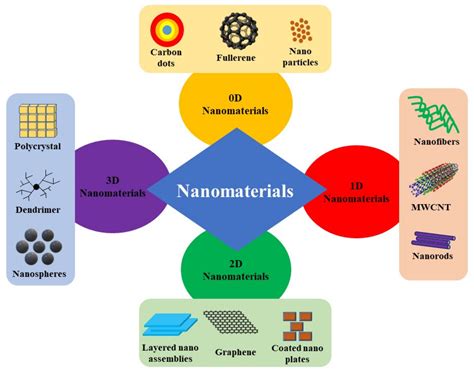

- Nanomaterial-based joining: The use of nanomaterials in joining technologies offers the potential for improved strength and durability.

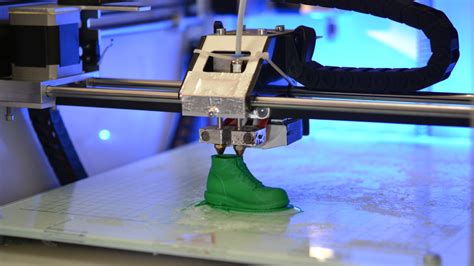

- 3D printing: The development of 3D printing technologies offers the potential for complex and innovative joining geometries.

Image Gallery of Superior Joining Technologies

What are the advantages of superior joining technologies?

+Superior joining technologies offer several advantages, including increased strength and durability, improved quality and consistency, increased efficiency and productivity, and greater design flexibility.

What are the challenges and limitations of superior joining technologies?

+The challenges and limitations of superior joining technologies include cost and complexity, material compatibility issues, and quality control requirements.

What are the future developments in superior joining technologies?

+The future developments in superior joining technologies include advanced welding techniques, nanomaterial-based joining, and 3D printing.

We hope this article has provided a comprehensive overview of superior joining technologies and their importance in advancing manufacturing. By understanding the advantages, challenges, and future developments in superior joining technologies, manufacturers can make informed decisions about how to improve their production processes and create innovative products.