Intro

Discover the intricacies of tank and barrel manufacturing and inspection processes. Learn about the latest industry standards, materials, and technologies used in fabrication, welding, and testing. Understand the importance of quality control, safety protocols, and regulatory compliance in producing high-quality storage containers for various industries, including oil and gas, chemical, and food processing.

Tank and barrel manufacturing and inspection processes are crucial in ensuring the quality and safety of these containers, which are used in various industries such as oil and gas, chemical, and food processing. The manufacturing process involves several stages, from design and fabrication to testing and inspection. In this article, we will delve into the details of tank and barrel manufacturing and inspection processes, highlighting their importance, benefits, and key considerations.

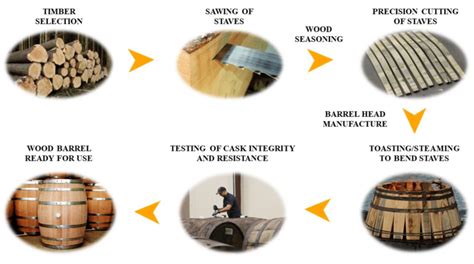

Design and Fabrication

The design and fabrication stage is critical in tank and barrel manufacturing. The design process involves creating a detailed blueprint of the tank or barrel, taking into account factors such as size, material, and intended use. The fabrication process involves cutting, welding, and shaping the material to create the desired shape and size.

Material Selection

The choice of material is crucial in tank and barrel manufacturing. The most common materials used are stainless steel, carbon steel, and fiberglass. Each material has its own strengths and weaknesses, and the choice of material depends on the intended use of the tank or barrel.

Welding and Assembly

Once the material has been fabricated, the next stage is welding and assembly. This involves joining the individual components together using welding techniques such as shielded metal arc welding (SMAW) or gas metal arc welding (GMAW). The assembly process involves attaching fittings, valves, and other components to the tank or barrel.

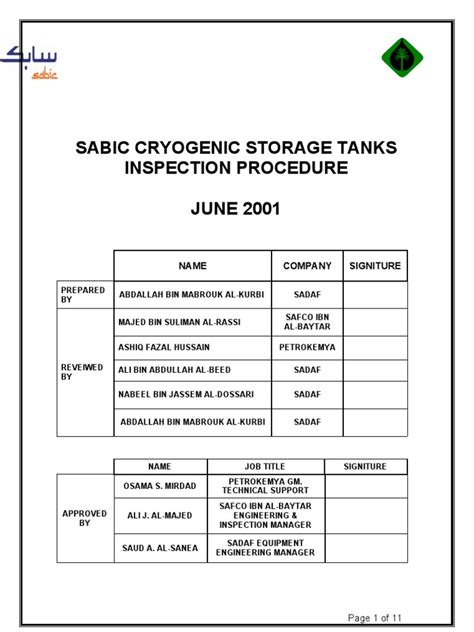

Testing and Inspection

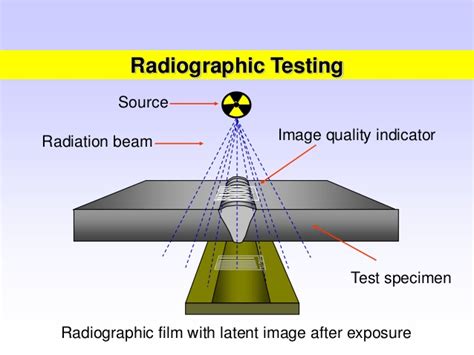

Testing and inspection are critical stages in tank and barrel manufacturing. The testing process involves subjecting the tank or barrel to various tests such as hydrostatic testing, pneumatic testing, and radiographic testing. These tests are designed to ensure that the tank or barrel is leak-free and can withstand the intended pressure.

Non-Destructive Testing (NDT)

Non-destructive testing (NDT) is a critical stage in tank and barrel inspection. NDT involves using various techniques such as ultrasonic testing, radiographic testing, and magnetic particle testing to inspect the tank or barrel without causing damage.

Benefits of NDT

NDT has several benefits, including:

- Improved safety: NDT helps to detect defects and flaws in the tank or barrel, which can help to prevent accidents and ensure safe operation.

- Cost savings: NDT can help to reduce costs by detecting defects early, which can help to prevent costly repairs and downtime.

- Increased efficiency: NDT can help to improve efficiency by reducing the need for destructive testing and minimizing the risk of defects.

Gallery of Tank and Barrel Manufacturing and Inspection Processes

Tank and Barrel Manufacturing and Inspection Processes

Frequently Asked Questions

What is the importance of tank and barrel manufacturing and inspection processes?

+Tank and barrel manufacturing and inspection processes are crucial in ensuring the quality and safety of these containers, which are used in various industries such as oil and gas, chemical, and food processing.

What are the benefits of non-destructive testing (NDT) in tank and barrel inspection?

+NDT has several benefits, including improved safety, cost savings, and increased efficiency.

What are the common materials used in tank and barrel manufacturing?

+The most common materials used are stainless steel, carbon steel, and fiberglass.

We hope this article has provided valuable insights into tank and barrel manufacturing and inspection processes. These processes are critical in ensuring the quality and safety of these containers, which are used in various industries. By understanding the importance of these processes, you can make informed decisions when selecting a tank or barrel for your specific needs. If you have any further questions or concerns, please do not hesitate to contact us.