Intro

Master the art of precision cutting with optimal torch settings. Learn how to balance temperature, gas flow, and flame type for safe and accurate cuts. Discover the importance of adjusting settings for different materials, thicknesses, and applications. Improve your technique and reduce risks with expert guidance on torch settings for precision cutting.

The art of torch cutting requires a combination of skill, attention to detail, and the right equipment settings. When it comes to cutting precision and safety, the optimal torch settings are crucial. In this article, we will explore the importance of proper torch settings, the factors that affect cutting precision and safety, and provide guidelines for achieving optimal settings.

The Importance of Proper Torch Settings

Proper torch settings are essential for achieving precise cuts while ensuring operator safety. A torch that is not set correctly can lead to a range of problems, including:

- Inaccurate cuts

- Excessive heat input

- Warping or distortion of the material

- Injury to the operator

Factors Affecting Cutting Precision and Safety

Several factors can affect cutting precision and safety, including:

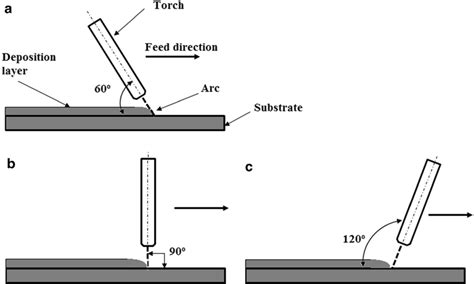

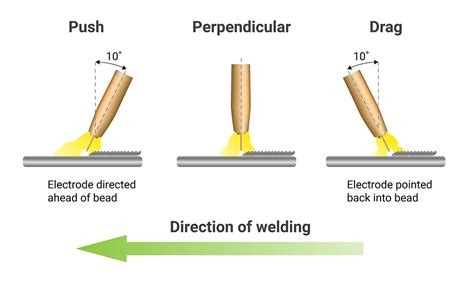

- Torch angle: The angle at which the torch is held can significantly impact cutting precision. A torch that is held at too shallow an angle can result in a lack of precision, while a torch held at too steep an angle can cause the flame to impinge on the surrounding material.

- Torch-to-work distance: The distance between the torch and the workpiece is critical for maintaining a stable flame and achieving precise cuts. A torch that is too close to the workpiece can cause the flame to become unstable, while a torch that is too far away can result in a lack of precision.

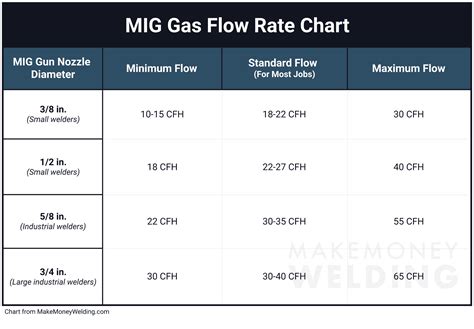

- Gas flow rates: The flow rates of the gases used in the torch can significantly impact cutting precision and safety. Incorrect gas flow rates can cause the flame to become unstable or produce excessive heat input.

- Cutting speed: The speed at which the torch is moved can also impact cutting precision. A torch that is moved too quickly can result in a lack of precision, while a torch that is moved too slowly can cause excessive heat input.

Guidelines for Achieving Optimal Torch Settings

To achieve optimal torch settings, follow these guidelines:

Torch Angle

- Hold the torch at an angle of 20-30 degrees to the workpiece.

- Adjust the torch angle as needed to achieve the desired level of precision.

Torch-to-Work Distance

- Maintain a distance of 1/8 inch to 1/4 inch (3 mm to 6 mm) between the torch and the workpiece.

- Adjust the torch-to-work distance as needed to achieve the desired level of precision.

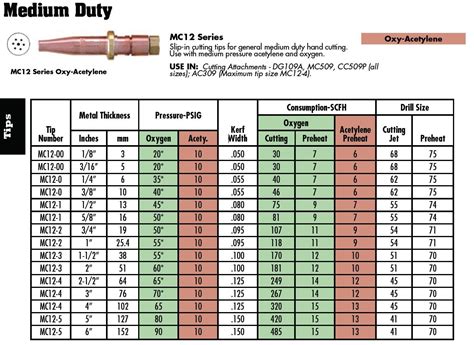

Gas Flow Rates

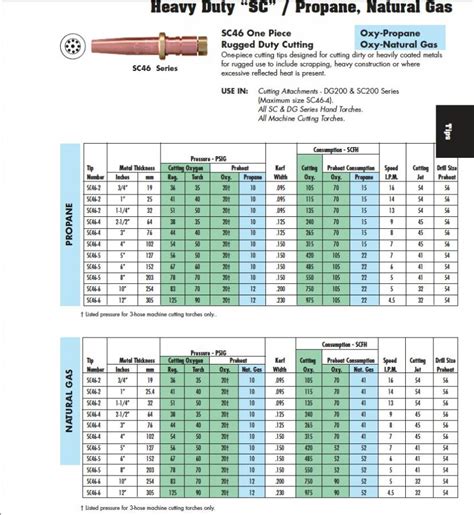

- Use the recommended gas flow rates for the specific torch and material being cut.

- Adjust the gas flow rates as needed to achieve a stable flame and precise cuts.

Cutting Speed

- Move the torch at a speed of 10-20 inches per minute (25 cm to 50 cm per minute).

- Adjust the cutting speed as needed to achieve the desired level of precision.

Additional Tips for Optimal Torch Settings

- Use a torch with a stable flame: A torch with a stable flame is essential for achieving precise cuts. Look for a torch with a reputation for producing a stable flame.

- Monitor the flame: Monitor the flame regularly to ensure it remains stable and is producing the desired level of precision.

- Adjust the torch settings as needed: Adjust the torch settings as needed to achieve the desired level of precision and safety.

Safety Precautions for Torch Cutting

Torch cutting can be a safe process if the proper safety precautions are taken. Here are some safety precautions to consider:

- Wear protective gear: Wear protective gear, including gloves, safety glasses, and a face shield, to protect against heat, sparks, and debris.

- Use a fire-resistant material: Use a fire-resistant material, such as a welding blanket or fire-resistant mat, to protect against sparks and debris.

- Keep the work area clean: Keep the work area clean and clear of debris to prevent accidents.

- Monitor the torch: Monitor the torch regularly to ensure it remains in good working condition.

Conclusion

Achieving optimal torch settings is crucial for cutting precision and safety. By following the guidelines outlined in this article, you can ensure that your torch is set correctly and that you are taking the necessary safety precautions. Remember to monitor the torch regularly and adjust the settings as needed to achieve the desired level of precision and safety.

Torch Cutting Image Gallery

FAQs

What is the optimal torch angle for precision cutting?

+The optimal torch angle for precision cutting is between 20-30 degrees.

What are the safety precautions for torch cutting?

+The safety precautions for torch cutting include wearing protective gear, using a fire-resistant material, keeping the work area clean, and monitoring the torch regularly.

What is the importance of proper torch settings for cutting precision and safety?

+Proper torch settings are essential for achieving precise cuts while ensuring operator safety. Incorrect torch settings can lead to a range of problems, including inaccurate cuts, excessive heat input, warping or distortion of the material, and injury to the operator.