Intro

Streamline electrical connections with feed thru lugs, a game-changing solution for simplifying wiring processes. Discover how these innovative lugs eliminate tedious stripping and twisting, reducing labor costs and improving safety. Learn about the benefits, applications, and installation tips for feed thru lugs, the ultimate electrical connectivity solution.

Feed thru lugs have revolutionized the way electrical connections are made, offering a more efficient and reliable solution for various industries. As technology continues to advance, the demand for faster and more secure connections has increased, making feed thru lugs an essential component in many electrical systems.

Electrical connections are a critical aspect of various industries, including construction, manufacturing, and telecommunications. However, traditional connection methods can be time-consuming, labor-intensive, and prone to errors. Feed thru lugs have addressed these challenges by providing a simple, efficient, and secure way to connect electrical wires.

In this article, we will delve into the world of feed thru lugs, exploring their benefits, working mechanisms, and applications. We will also discuss the different types of feed thru lugs, their selection criteria, and installation procedures.

What are Feed Thru Lugs?

Feed thru lugs are electrical connectors that allow wires to be connected through a single opening, eliminating the need for multiple connectors and simplifying the connection process. They consist of a metal or plastic body with a hole or slot that enables wires to pass through, and a screw or clamp that secures the wire in place.

Benefits of Feed Thru Lugs

Feed thru lugs offer several benefits that make them an attractive solution for electrical connections:

- Simplified connections: Feed thru lugs reduce the number of connectors required, making it easier to connect wires.

- Increased efficiency: With feed thru lugs, connections can be made faster, reducing labor costs and improving productivity.

- Improved reliability: Feed thru lugs provide a secure connection, minimizing the risk of errors and electrical faults.

- Space-saving design: Feed thru lugs are compact, making them ideal for applications where space is limited.

Working Mechanisms of Feed Thru Lugs

Feed thru lugs work by allowing wires to pass through a single opening, which is then secured by a screw or clamp. The wire is fed through the lug, and the screw or clamp is tightened to hold the wire in place. This creates a secure connection that can withstand various environmental conditions.

Types of Feed Thru Lugs

There are several types of feed thru lugs available, each designed for specific applications:

- Screw-type feed thru lugs: These lugs use a screw to secure the wire in place.

- Clamp-type feed thru lugs: These lugs use a clamp to secure the wire in place.

- Push-in feed thru lugs: These lugs use a push-in mechanism to secure the wire in place.

- Insulated feed thru lugs: These lugs have an insulated body to prevent electrical shock.

Selection Criteria for Feed Thru Lugs

When selecting feed thru lugs, several factors should be considered:

- Wire size: The lug should be compatible with the wire size.

- Material: The lug material should be compatible with the wire material.

- Environmental conditions: The lug should be able to withstand the environmental conditions of the application.

- Connection type: The lug should be suitable for the type of connection required.

Installation Procedures for Feed Thru Lugs

Installing feed thru lugs is a relatively simple process:

- Prepare the wire: Strip the wire to the required length and remove any insulation.

- Insert the wire: Insert the wire through the lug, ensuring it is properly seated.

- Secure the wire: Tighten the screw or clamp to secure the wire in place.

- Test the connection: Test the connection to ensure it is secure and functioning properly.

Applications of Feed Thru Lugs

Feed thru lugs are used in various industries, including:

- Construction: Feed thru lugs are used in building construction to connect electrical wires.

- Manufacturing: Feed thru lugs are used in manufacturing to connect electrical wires in machinery and equipment.

- Telecommunications: Feed thru lugs are used in telecommunications to connect electrical wires in communication systems.

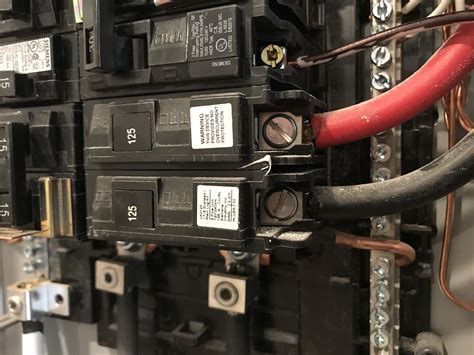

Gallery of Feed Thru Lugs

Feed Thru Lugs Image Gallery

FAQs

What are feed thru lugs?

+Feed thru lugs are electrical connectors that allow wires to be connected through a single opening.

What are the benefits of feed thru lugs?

+Feed thru lugs offer simplified connections, increased efficiency, improved reliability, and a space-saving design.

How do feed thru lugs work?

+Feed thru lugs work by allowing wires to pass through a single opening, which is then secured by a screw or clamp.

In conclusion, feed thru lugs have revolutionized the way electrical connections are made, offering a more efficient and reliable solution for various industries. With their simplified connections, increased efficiency, and improved reliability, feed thru lugs have become an essential component in many electrical systems. Whether you're a construction professional, a manufacturer, or a telecommunications expert, feed thru lugs are an ideal solution for your electrical connection needs.

We hope this article has provided you with valuable insights into the world of feed thru lugs. If you have any questions or comments, please feel free to share them with us.